Bandage rolling machine

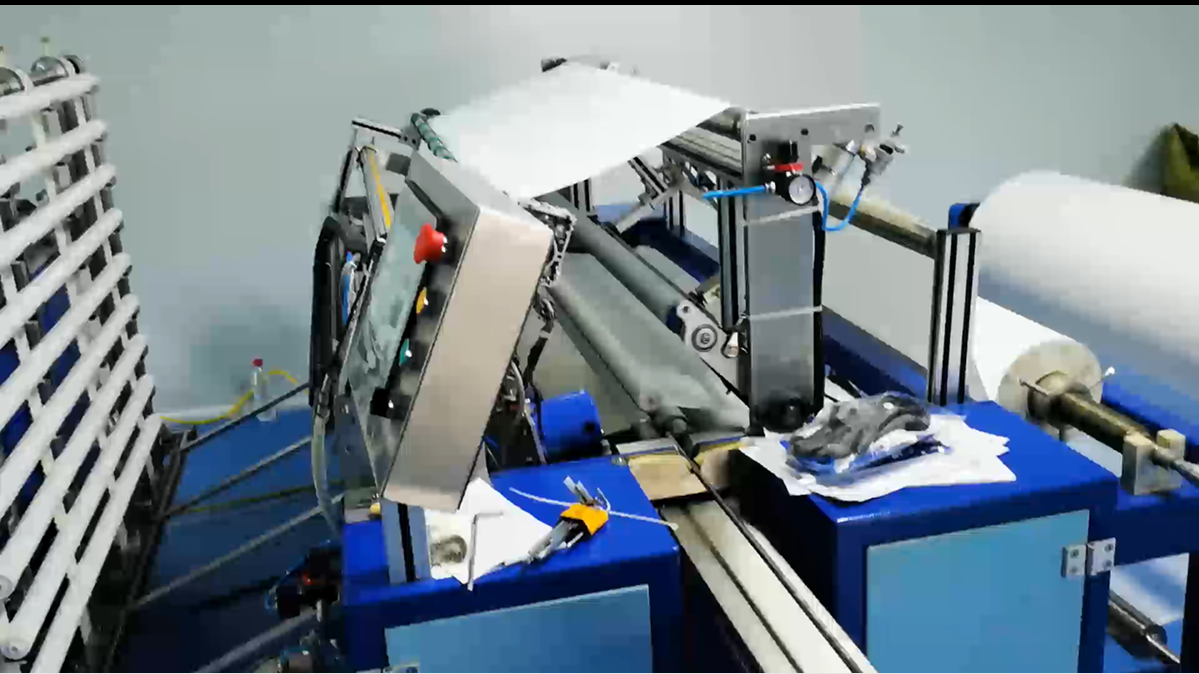

Elastic bandage rolling and packing production line

A: Elasticizing

Step 1:Bandage large rolls directly on the machine

Step 2:High-temperature elasticization with precisely adjustable temperature and adjustable feeding speed.

B: Rolling

Step 1: Automatically rolling

Step 2: Automatically thermal cutting

Step 3: Automatically discharging

C: Packing

Step 1: Automatic material handling

Step 2: Into the pillow packaging machine

Step 3: Empty packet recognition, automatic packaging and discharging

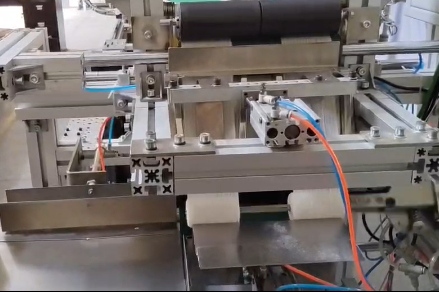

Automatic bandage wrapping paper and slitting production line

1.This machine can realize automatic core pulling, roll forming and roll dropping, which reduces the process flow and saves labor.

2.The finished products produced by this machine are flat and consistent in appearance with high qualification rate.

3.Blank unwind, bi-directional horizontal adjustment; individually adjustable. Precision linear guide rails for accurate and durable positioning.

4.Unwinding with pneumatic tension brake: active unwind synchronizes the unwind tension to reduce shrinkage.

5.This machine is equipped with a blank auxiliary winding system; maximum load 250KG pneumatic linkage device horizontal winding.

6.Reduce the labor intensity of operators, safe and reliable.

Elastic Bandage Overlocking Sewing Roll Production Line (sewing both ends)

Elastic bandage overlock sewing production line is based on the function of the original bandage machine, fused with the function of overlock sewing production line, so that it can be bandage head overlock sewing technology processing.

Elastic bandage production line

- Used for small rolls of elastic woven bandages;

- The elastic bandage on the machine is automatically fed, rolled, fixed-length cut, discharge, raw

- Accurate control of roll weight and length deviation.

- The equipment control system uses touch screen and PLC to adjust parameters conveniently.

- Four universal wheels are installed at the bottom of the equipment rack for quick movement.

- The diameter of the cloth roll is allowed to be plus or minus 2mm.

Recommend Products

-

Cotton Swab Machine

Introduction Highlights::Automatic bagging and sealing featuresThe total length of this swab machine is about... -

Warping Machine

It is suitable for various elastic, inelastic and trademark high-quality warping. This machine uses a frequency converte... -

Elastic bandage rolling and packing production line

A: Elasticizing Step 1:Bandage large rolls directly on the machine Step 2:High-temperature elasticizat... -

Automatic bandage wrapping paper and slitting production line

1.This machine can realize automatic core pulling, roll forming and roll dropping, which reduces the process flow and sa... -

Elastic Bandage Overlocking Sewing Roll Production Line (sewing both ends)

Elastic bandage overlock sewing production line is based on the function of the original bandage machine, fused with the...