Recently, Foshan Binhong Equipment Co。, Ltd。 (hereinafter referred to as "Binghong") has determined the research and development plan and specific construction details of the non——woven fabric folding machine after in——depth discussions with customers and full research with the technical department。 The on——time delivery of the folding machine to customers has laid a solid foundation。 The research and development, manufacturing and service of non——woven fabric folding machine equipment invested and developed by Binhong has completed the feasibility design of the project, and the project is about to start full——scale construction。

Binhong, as an established enterprise in the gauze folding industry, is a high——tech enterprise certified by the Guangdong Provincial Department of Science and Technology, and is also a stationed enterprise of craftsmen in Dacheng。 Since its establishment in Nanhai District, Foshan City in 2008, Binhong has been mainly engaged in the four core businesses of gauze automatic sewing production line, gauze folding machine, non——woven fabric folding machine, and bandage rolling machine。 Now it has developed into a technology research and development, high——end manufacturing A professional R&D and innovative enterprise integrating technical services。

Figure 1: The non——woven fabric is spread out on the machine

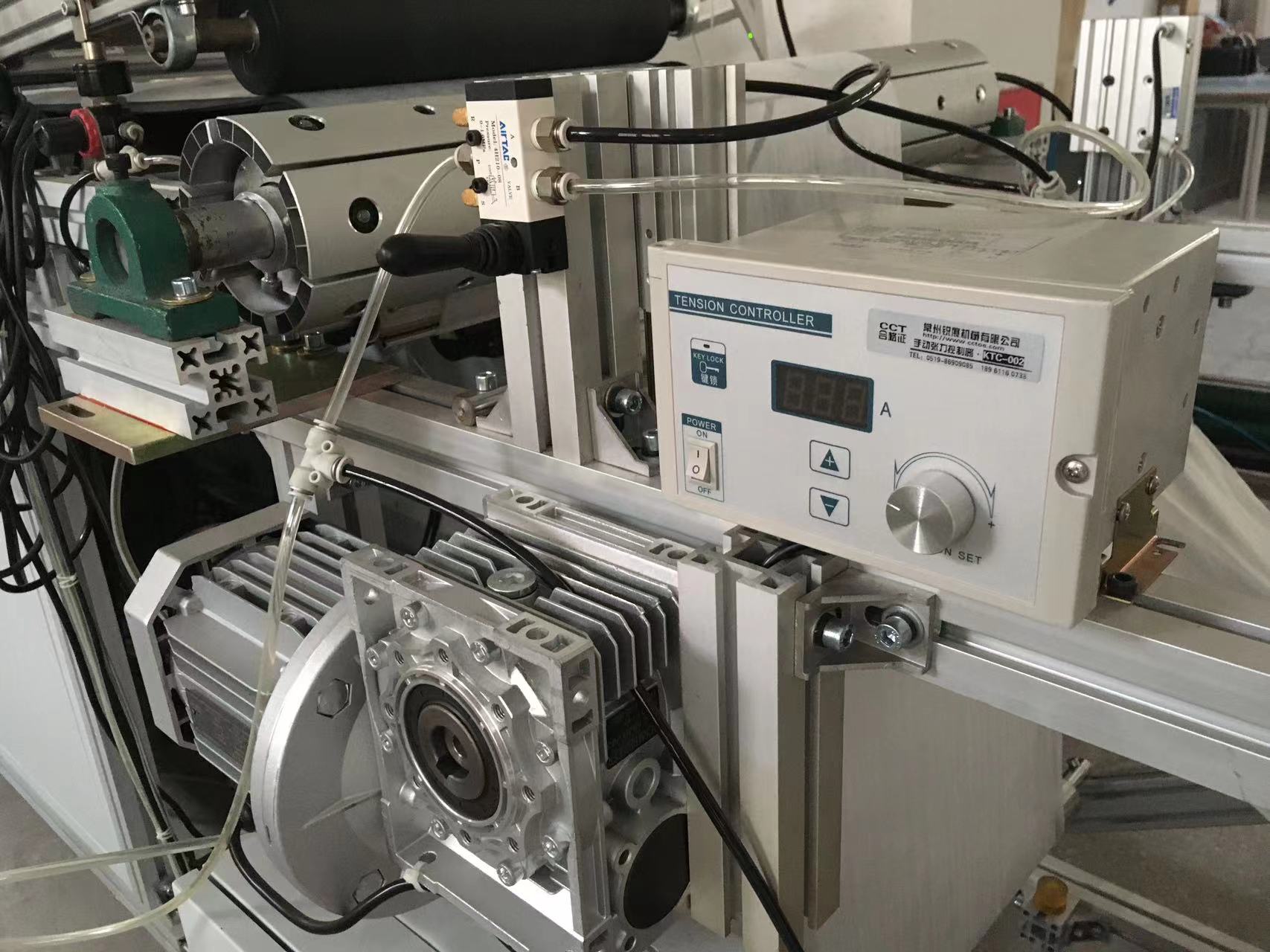

"The most difficult thing in the non——woven fabric folding operation is to keep the folded product from deforming。 This year, we have newly developed a non——woven fabric folding machine product with automatic adjustable specifications —— a compatible non——woven fabric folding machine, which uses The electronic induction probe is linked with the mechanical pressure detector to detect the elastic deformation and tension change。 After the feedback electrical signal is calculated by the control computer, the internal operating parameters of the non——woven fabric folding machine are automatically adjusted to stretch the non——woven fabric with deformation tendency。 The raw material of the cloth is removed and the wrinkles are erased to achieve the purpose of flat folding the non——woven fabric。

Figure 2: Tension control device of non——woven fabric folding machine

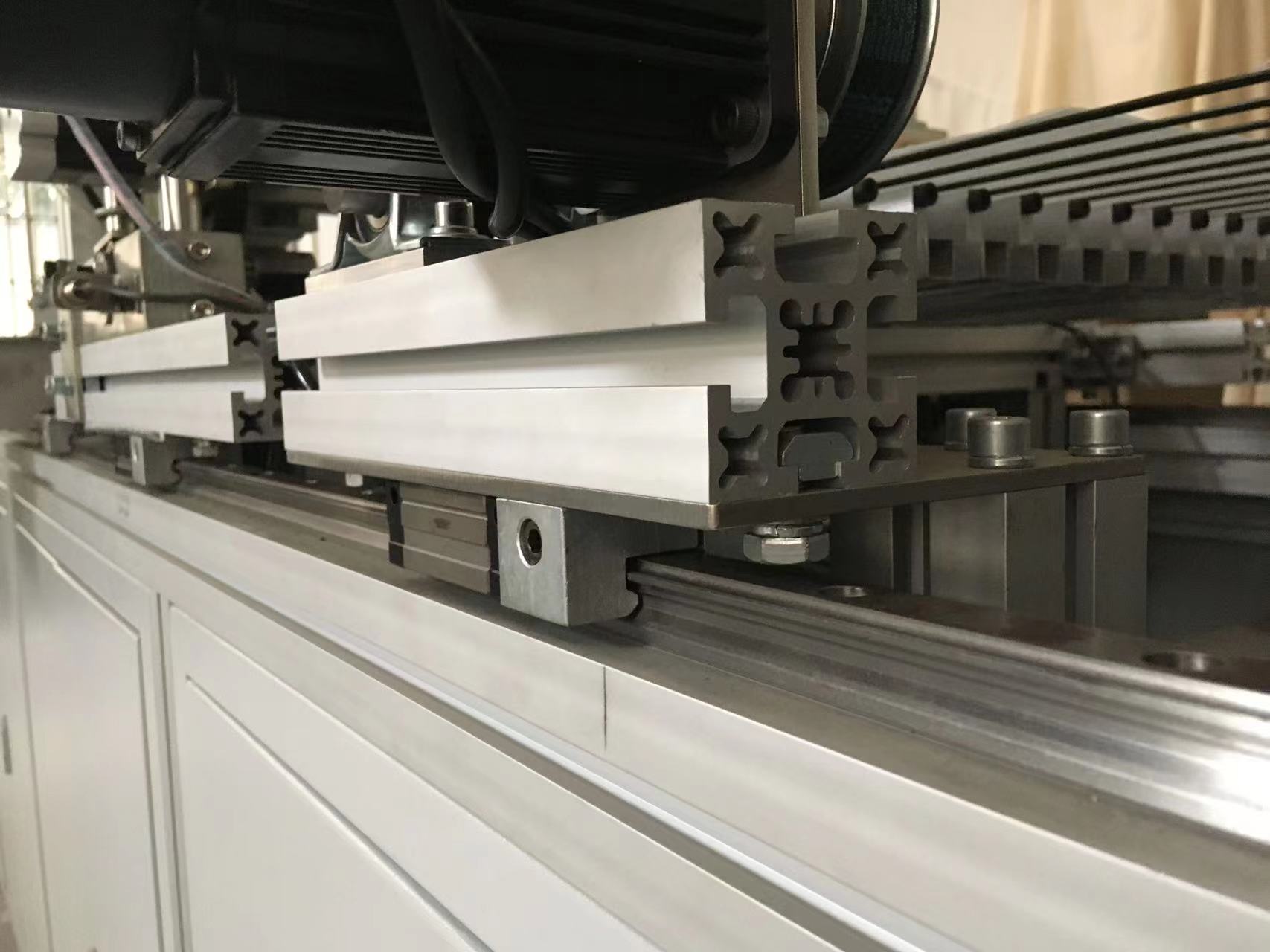

In this way, the wrinkles of the product can be reduced, the qualified rate of the product can be effectively increased, and the failure time can be reduced。 "Gui Renbing, general manager of Binhong and director of Dacheng Craftsman Studio, said。 In order to make the equipment more compatible, especially according to the appearance and movement trajectory of the equipment, important movements such as moving the cutter and turning the plate are realized by means of sliding guide rails。 Parts, so that it can match the actual needs of non——woven fabrics with different specifications for cutting and folding。

Figure 3: Fixed Slide Rail Adjustable Position

At present, Binhong has reached in——depth cooperation with relevant enterprises in central and northeastern China by virtue of this product。