Products

Specializing in the development, production and operation of complete sets of textile equipment. The main products are: automatic gauze folding, rolling, placing blue barium sheet, folding, sewing equipment; integrated medical gauze folding sewing production line; shrinking gauze folding machine; belly pad folding machine; vertical and horizontal gauze folding machine; fully automatic N95 mask machine; medical inelastic bandage forming machine; medical elastic bandage forming machine and other equipment. The above equipment is easy to operate, beautiful in appearance and durable.

Cotton Swab Machine

Introduction

Highlights::Automatic bagging and sealing features

The total length of this swab machine is about 6 meters, the surface is made of stainless steel, beautiful and easy to clean. Compared with the traditional cotton swab machine greatly save the workshop space. The main machine adopts the new type of flatbed machine, the cotton head is even and beautiful, the machine can reach a stable speed of 1000 pieces / min, the stick is convenient, equipped with a lower stick device, more saving raw materials. High-quality new design M-type drying box (the first in the country), covers an area of small, long drying time, low temperature, energy-saving and power-saving and minimize the cost of production, the perfect solution to the problem of mold due to humidity, long downtime will not yellow. The machine is the domestic intelligent professional machinery, perfect performance, equipped with automatic bagging device, automatic sealing device, from the feed to the completion of packaging, once in place, the whole robot operation, no artificial contact with the product caused by product pollution. Under normal operation, the whole machine can be operated by one person, which saves 3-4 workers compared with the common old medical swab machine. It really achieves labor saving, environmental protection and hygiene.

Warping Machine

It is suitable for various elastic, inelastic and trademark high-quality warping. This machine uses a frequency converter to control the motor speed. It is driven by the friction between the roller and the warp plate. The friction force can be adjusted as required to make the warp yarn on the plate meets the best requirements.

Characteristic

a. Electronic calculator, freely choose the required length setting to ensure accurate quantification and reduce yarn waste.

b. The automatic brake device for yarn breakage ensures that the yarn brakes in time before entering the warp disc.

c. The retractable device of the yarn steel buckle can be adjusted according to the density of the warping.

d. The creel precision yarn feeder ensures that the tension is consistent from the beginning of the warping to the completion of the warping.

e. The number of creels is divided into 100 pcs for selection.

Elastic bandage rolling and packing production line

A: Elasticizing

Step 1:Bandage large rolls directly on the machine

Step 2:High-temperature elasticization with precisely adjustable temperature and adjustable feeding speed.

B: Rolling

Step 1: Automatically rolling

Step 2: Automatically thermal cutting

Step 3: Automatically discharging

C: Packing

Step 1: Automatic material handling

Step 2: Into the pillow packaging machine

Step 3: Empty packet recognition, automatic packaging and discharging

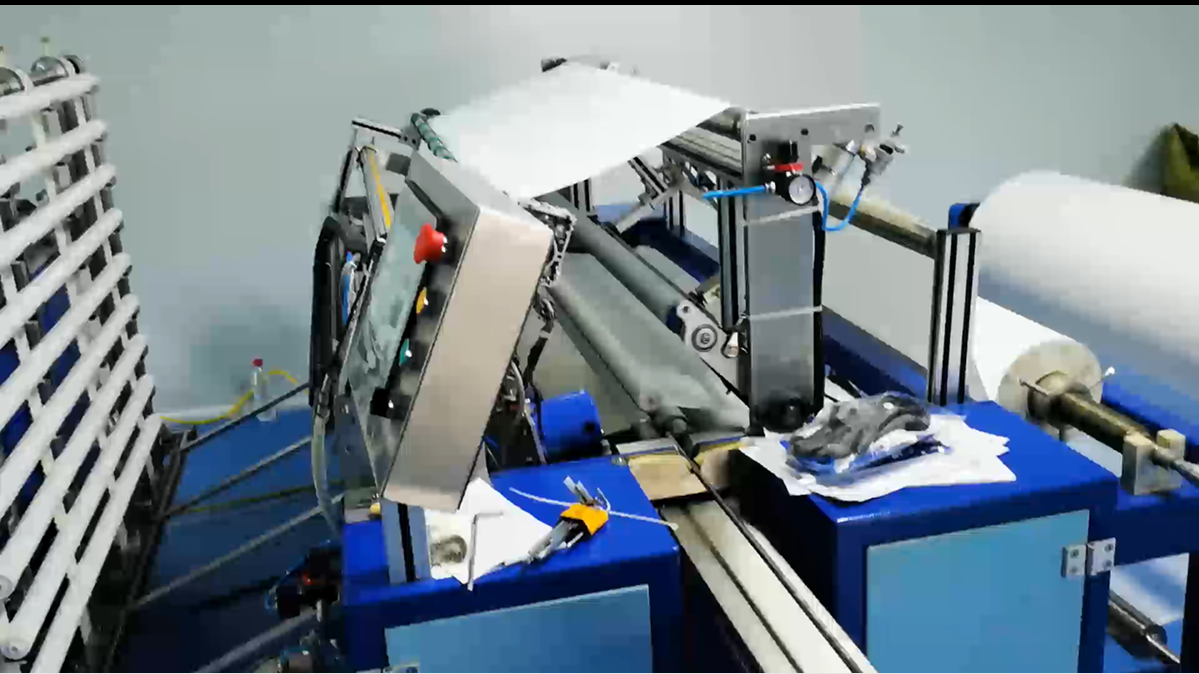

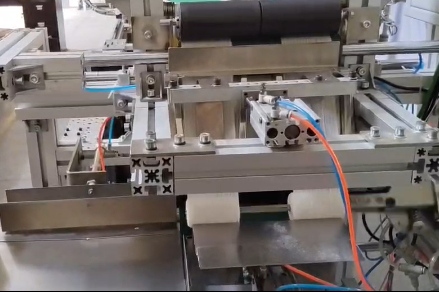

Automatic bandage wrapping paper and slitting production line

1.This machine can realize automatic core pulling, roll forming and roll dropping, which reduces the process flow and saves labor.

2.The finished products produced by this machine are flat and consistent in appearance with high qualification rate.

3.Blank unwind, bi-directional horizontal adjustment; individually adjustable. Precision linear guide rails for accurate and durable positioning.

4.Unwinding with pneumatic tension brake: active unwind synchronizes the unwind tension to reduce shrinkage.

5.This machine is equipped with a blank auxiliary winding system; maximum load 250KG pneumatic linkage device horizontal winding.

6.Reduce the labor intensity of operators, safe and reliable.

Elastic Bandage Overlocking Sewing Roll Production Line (sewing both ends)

Elastic bandage overlock sewing production line is based on the function of the original bandage machine, fused with the function of overlock sewing production line, so that it can be bandage head overlock sewing technology processing.

Recommend Products

-

Cotton Swab Machine

Introduction Highlights::Automatic bagging and sealing featuresThe total length of this swab machine is about... -

Warping Machine

It is suitable for various elastic, inelastic and trademark high-quality warping. This machine uses a frequency converte... -

Elastic bandage rolling and packing production line

A: Elasticizing Step 1:Bandage large rolls directly on the machine Step 2:High-temperature elasticizat... -

Automatic bandage wrapping paper and slitting production line

1.This machine can realize automatic core pulling, roll forming and roll dropping, which reduces the process flow and sa... -

Elastic Bandage Overlocking Sewing Roll Production Line (sewing both ends)

Elastic bandage overlock sewing production line is based on the function of the original bandage machine, fused with the...